GA

Свойства

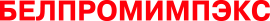

| Материал | (1) втулка: Сталь,(2) скребковая манжета: 90° твердость по Шору A нитрильный каучук |

| Модель | Скребковая манжета |

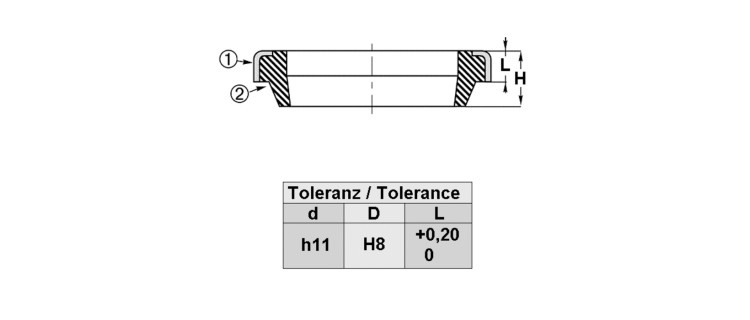

| Монтаж | впрессовывается в открытый паз |

| Скорость скольжения макс. | 0.5 m/s |

| Температура min. | -30 °C |

| Температура макс. | 100 °C |

| Применение | Гидравлика |

| Рабочие среды | Минеральное масло,Водные эмульсии |

99 Изделие

| Наименование |

d

mm |

D

mm |

L

mm |

H

mm |

Nuten gemäss |

|---|---|---|---|---|---|

| GA 10 16-3 | 10 | 16.0 | 3.0 | 4.5 | - |

| GA 10 19-3 | 10 | 18.9 | 2.9 | 5.0 | - |

| GA 10 20-5 | 10 | 20.0 | 5.0 | 8.0 | - |

| GA 12 18-3 | 12 | 18.0 | 3.5 | 5.0 | - |

| GA 12 20-4 | 12 | 20.0 | 4.0 | 6.0 | - |

| GA 12 22-5 | 12 | 22.0 | 5.0 | 8.0 | - |

| GA 14 20-3 | 14 | 20.0 | 3.0 | 4.5 | - |

| GA 14 22-3 | 14 | 22.0 | 3.0 | 4.0 | - |

| GA 16 22-3 | 16 | 22.0 | 3.0 | 4.0 | - |

| GA 16 26-5 | 16 | 26.0 | 5.0 | 8.0 | - |

| GA 18 28-5 | 18 | 28.0 | 5.0 | 7.0 | - |

| GA 18 28-7 | 18 | 28.0 | 7.0 | 10.0 | ISO 5597 |

| GA 20 26-3 | 20 | 26.0 | 3.5 | 5.0 | - |

| GA 20 28-3 | 20 | 28.0 | 3.5 | 5.0 | - |

| GA 20 28-5 | 20 | 28.0 | 5.0 | 7.0 | - |

| GA 20 30-4 | 20 | 30.0 | 4.0 | 6.0 | - |

| GA 20 30-5 | 20 | 30.0 | 5.0 | 8.0 | - |

| GA 20 30-7 | 20 | 30.0 | 7.0 | 10.0 | ISO 5597 |

| GA 20 35-7 | 20 | 35.0 | 7.0 | 10.0 | - |

| GA 22 28-5 | 22 | 28.0 | 5.0 | 9.0 | - |

| GA 22 30-4 | 22 | 30.0 | 4.0 | 7.0 | - |

| GA 22 32-5 | 22 | 32.0 | 5.0 | 7.0 | - |

| GA 22 32-7 | 22 | 32.0 | 7.0 | 10.0 | ISO 5597 |

| GA 22 35-5 | 22 | 35.0 | 5.0 | 8.0 | - |

| GA 25 35-5 | 25 | 35.0 | 5.0 | 8.0 | - |

| GA 25 35-7 | 25 | 35.0 | 7.0 | 10.0 | ISO 5597 |

| GA 28 38-5 | 28 | 38.0 | 5.0 | 8.0 | - |

| GA 28 38-7 | 28 | 38.0 | 7.0 | 10.0 | - |

| GA 28 40-7 | 28 | 40.0 | 7.0 | 10.0 | - |

| GA 30 40-5 | 30 | 40.0 | 5.0 | 8.0 | - |

| GA 30 40-7 | 30 | 40.0 | 7.0 | 10.0 | - |

| GA 30 45-5 | 30 | 45.0 | 5.0 | 8.0 | - |

| GA 32 40-4 | 32 | 40.0 | 4.0 | 7.0 | - |

| GA 32 42-5 | 32 | 42.0 | 5.0 | 7.0 | - |

| GA 32 42-7 | 32 | 42.0 | 7.0 | 10.0 | - |

| GA 32 45-4 | 32 | 45.0 | 4.0 | 8.0 | - |

| GA 32 45-7 | 32 | 45.0 | 7.0 | 10.0 | - |

| GA 33 43-5 | 33 | 43.0 | 5.0 | 8.0 | - |

| GA 35 45-5 | 35 | 45.0 | 5.0 | 8.0 | - |

| GA 35 45-7 | 35 | 45.0 | 7.0 | 10.0 | ISO 5597 |

| GA 35 47-7 | 35 | 47.0 | 7.0 | 10.0 | - |

| GA 36 45-7 | 36 | 45.0 | 7.0 | 10.0 | - |

| GA 36 46-5 | 36 | 46.0 | 5.0 | 8.0 | - |

| GA 3747 - 5 | 37 | 47 | 5.0 | - | - |

| GA 38 48-7 | 38 | 48.0 | 7.0 | 10.0 | - |

| GA 40 50-5 | 40 | 50.0 | 5.0 | 8.0 | - |

| GA 40 50-7 | 40 | 50.0 | 7.0 | 10.0 | ISO 5597 |

| GA 40 52-5 | 40 | 52.0 | 5.0 | 8.0 | - |

| GA 42 52-7 | 42 | 52.0 | 7.0 | 10.0 | - |

| GA 45 55-7 | 45 | 55.0 | 7.0 | 10.0 | ISO 5597 |

| GA 45 60-7 | 45 | 60.0 | 7.0 | 10.0 | - |

| GA 48 60-7 | 48 | 60.0 | 7.0 | 10.0 | - |

| GA 50 56-5 | 50 | 56.0 | 5.0 | 8.0 | - |

| GA 50 60-5 | 50 | 60.0 | 5.0 | 8.0 | - |

| GA 50 60-7 | 50 | 60.0 | 7.0 | 10.0 | ISO 5597 |

| GA 50 65-5 | 50 | 65.0 | 5.0 | 8.0 | - |

| GA 50 65-7 | 50 | 65.0 | 7.0 | 10.0 | - |

| GA 52 62-7 | 52 | 62.0 | 7.0 | 10.0 | - |

| GA 55 63-7 | 55 | 63.0 | 7.0 | 10.0 | - |

| GA 55 65-7 | 55 | 65.0 | 7.0 | 10.0 | - |

| GA 55 70-7 | 55 | 70.0 | 7.0 | 10.0 | - |

| GA 55 80-5 | 55 | 80.0 | 5.0 | 8.0 | - |

| GA 56 65-7 | 56 | 65.0 | 7.0 | 10.0 | - |

| GA 56 66-5 | 56 | 66.0 | 5.0 | 8.0 | - |

| GA 56 66-7 | 56 | 66.0 | 7.0 | 10.0 | ISO 5597 |

| GA 60 70-5 | 60 | 70.0 | 5.0 | 7.0 | - |

| GA 60 70-7 | 60 | 70.0 | 7.0 | 10.0 | - |

| GA 60 74-5 | 60 | 74.0 | 5.0 | 8.0 | - |

| GA 60 75-7 | 60 | 75.0 | 7.0 | 10.0 | - |

| GA 63 75-7 | 63 | 75.0 | 7.0 | 10.0 | - |

| GA 63 83-5 | 63 | 83.0 | 5.0 | 8.0 | - |

| GA 65 75-7 | 65 | 75.0 | 7.0 | 10.0 | - |

| GA 70 80-5 | 70 | 80.0 | 5.0 | 7.0 | - |

| GA 70 80-7 | 70 | 80.0 | 7.0 | 10.0 | ISO 5597 |

| GA 75 85-7 | 75 | 85.0 | 7.0 | 10.0 | - |

| GA 75 87-5 | 75 | 87.0 | 5.0 | 7.0 | - |

| GA 80 90-7 | 80 | 90.0 | 7.0 | 10.0 | ISO 5597 |

| GA 85 95-7 | 85 | 95.0 | 7.0 | 10.0 | - |

| GA 90 100-5 | 90 | 100.0 | 5.0 | 7.0 | - |

| GA 90 100-7 | 90 | 100.0 | 7.0 | 10.0 | ISO 5597 |

| GA 95 105-7 | 95 | 105.0 | 7.0 | 10.0 | - |

| GA 100 110-5 | 100 | 110.0 | 5.0 | 7.0 | - |

| GA 100 110-7 | 100 | 110.0 | 7.0 | 10.0 | - |

| GA 105 115-7 | 105 | 115.0 | 7.0 | 10.0 | - |

| GA 110 120-7 | 110 | 120.0 | 7.0 | 10.0 | - |

| GA 115 125-7 | 115 | 125.0 | 7.0 | 10.0 | - |

| GA 120 130-7 | 120 | 130.0 | 7.0 | 10.0 | - |

| GA 125 140-7 | 125 | 140.0 | 7.0 | 10.0 | - |

| GA 125 140-9 | 125 | 140.0 | 9.0 | 12.0 | ISO 5597 |

| GA 130 145-9 | 130 | 145.0 | 9.0 | 12.0 | - |

| GA 135 145-7 | 135 | 145.0 | 7.0 | 10.0 | - |

| GA 135 150-9 | 135 | 150.0 | 9.0 | 12.0 | - |

| GA 140 150-7 | 140 | 150.0 | 7.0 | 10.0 | - |

| GA 140 155-9 | 140 | 155.0 | 9.0 | 12.0 | ISO 5597 |

| GA 150 165-9 | 150 | 165.0 | 9.0 | 12.0 | - |

| GA 160 175-9 | 160 | 175.0 | 9.0 | 12.0 | ISO 5597 |

| GA 170 185-10 | 170 | 185.0 | 10.0 | 14.0 | - |

| GA 180 195-10 | 180 | 195.0 | 10.0 | 14.0 | - |

| GA 200 220-12 | 200 | 220.0 | 12.0 | 16.0 | - |

Заявление об исключении ответственности

В виду большого ассортимента каталога и несмотря на тщательную проверку мы не можем исключить опечатки или ошибки. Окончательной спецификация считается после подтверждения заказа менеджером.